The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

Product advantages:

The laser welding machine adopts fiber laser source, which has high photoelectric conversion efficiency and long life of 100,000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times than that of YAG laser.

Features:

1. The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2. High cooling rate, which can weld fine weld structure and good joint performance.

3. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

4. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5. No consumables, small size, flexible processing, low operating and maintenance costs.

6. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

Application areas:Mainly aquatic stainless steel, carbon steel, aluminum alloy carbon steel, stainless steel, aluminum alloy, galvanized plate and other massive shell cabinets, hardware furniture lighting, guardrail doors and windows, new energy, mechanical and electrical products, mechanical and electrical products, etc.

1. Save manual: L -shaped left welding left and right welding, the machine does not interrupt the operation

2. Replacement of traditional welding: Reduce polishing, speed is 2-5 times faster

3. Six -axis welding is more flexible: welding can be welded at different angles, such as tube electric vehicles, furniture, etc.

4. Higher cooperative operation: two robots in large products can coordinate welded at the same time

5. Precision products are more cost -effective: seamless or small sheet metal welding. No need to send wire, save welding wire costs

Technology parameter:

| Laser power | 2000W |

| Center wavelength | 1070nm |

| Output power stability | <3% |

| Laser frequency | 0.5Hz-100KHz |

| Adjustable power range | 10-100% |

| Beam quality | 1.1 |

| Optimal operating environment | Temperature 0-40 ° C, humidity 20% -80% |

| Electricity demand | Robot AC380V, Laser system 220V. |

| Output fiber length | 10m |

| Welding speed | 0-120mm/s |

| Positioning precision of space | 0.05mm |

| Robot Max. Moving radius | 1550mm |

| Max. payload | 12kg |

| Cooling method | Water Cooling |

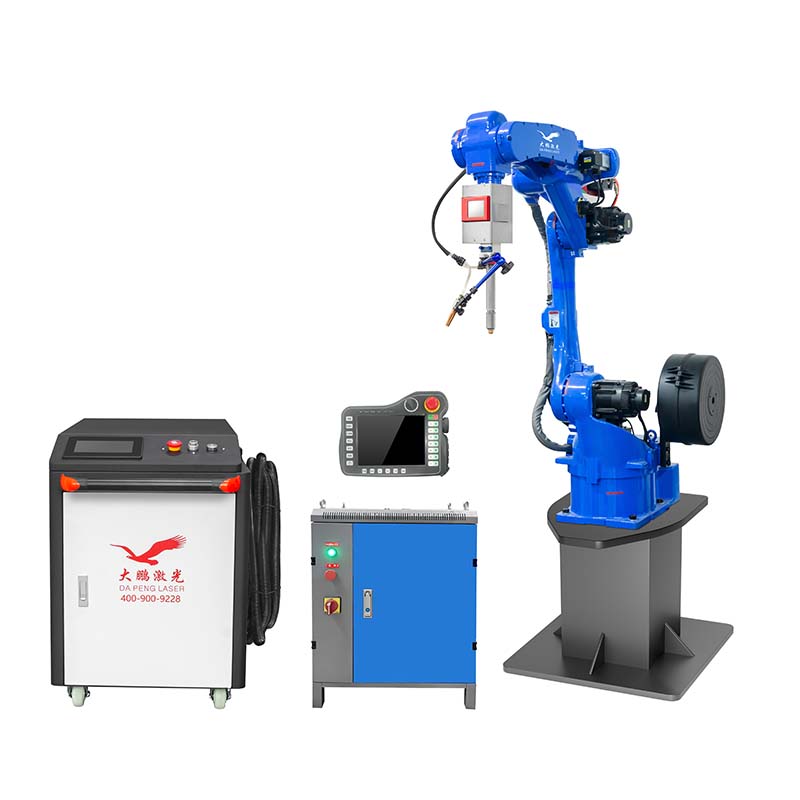

Machine configuration:

| Name | Specs | Place of origin |

| Cabinet | DP fiber welding cabinet | Shenzhen |

| Laser source | Raycus | China |

| Welding head | DP customized welding head | China |

| Robot | DP customized robot | China |

| Chiller | Hanli SCH-2000 | China |

| CCD camera | 20 times magnification | China |

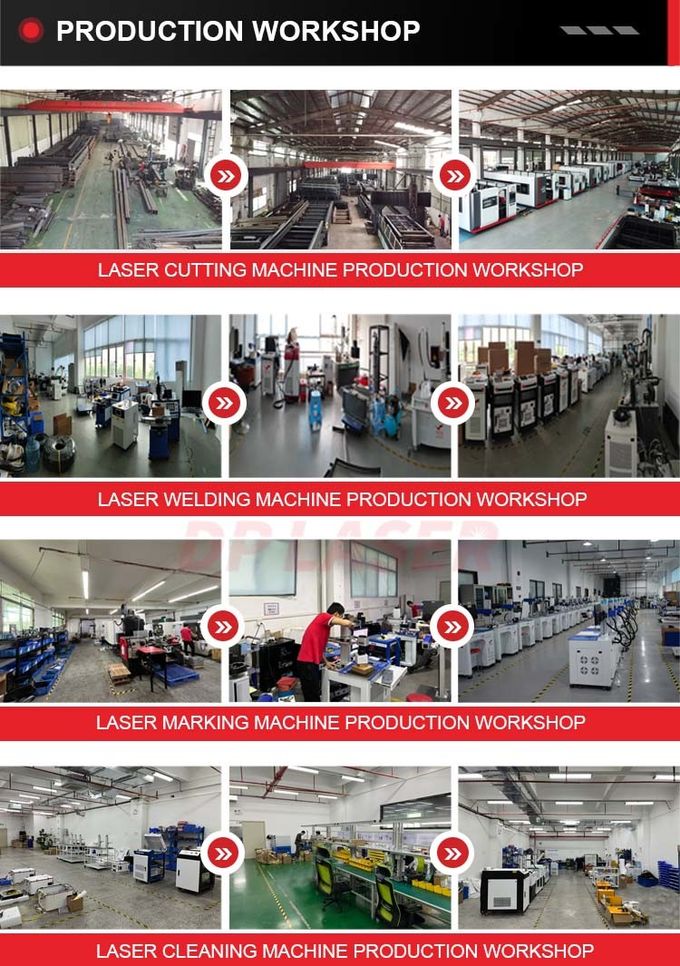

We are manufacturer of fiber laser cutting machine with 12 years of production experience.We offer complete machine solution,also provide laser source,CNC controller ,laserhead, water chiller,servo,custom made machine table,training and service,etc. one-stop solution!

Our core advantages:

1) Top 5 laser company in China. Sold 4500 units of laser machines in China market per year, with best price.

2) Usually have 50 units of laser marking machine(Fiber, CO2, UV, Mopa) in stock, lead time 3-5 days.

3) Fiber Laser cutting machine, (1000W-20,000W laser cutter), usually sell 50 units/month in China.

We are looking for distributor. Price is more competitive.

We have 250MB videos and manual reference, if you want, we can send you for free, please leave message.

manager@dapeng-laser.com Whatsapp:+8618565695703 Contact KENDY and send you machine teaching videos and manual for free.