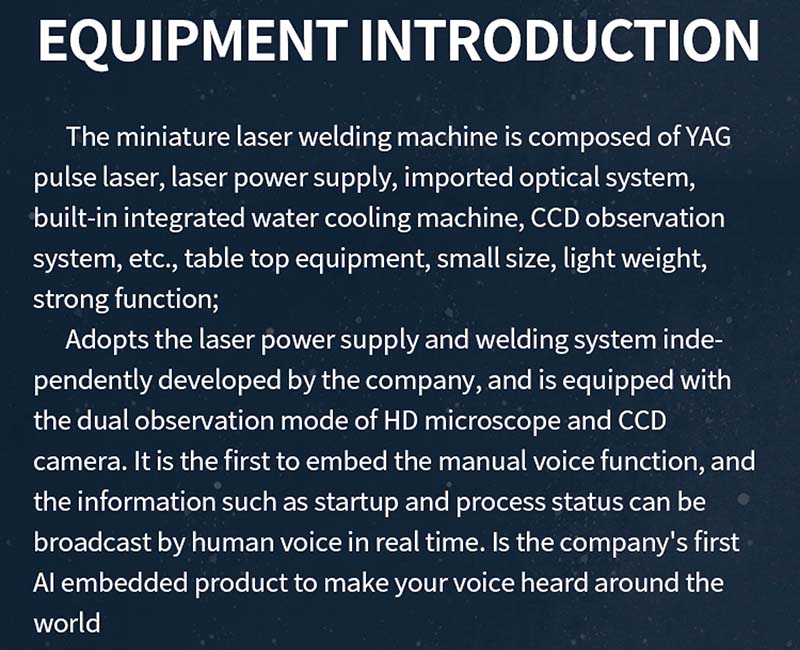

Jewelry laser welder is mainly used in perforating and spot welding of white gold, platinum, carbon steel. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool.

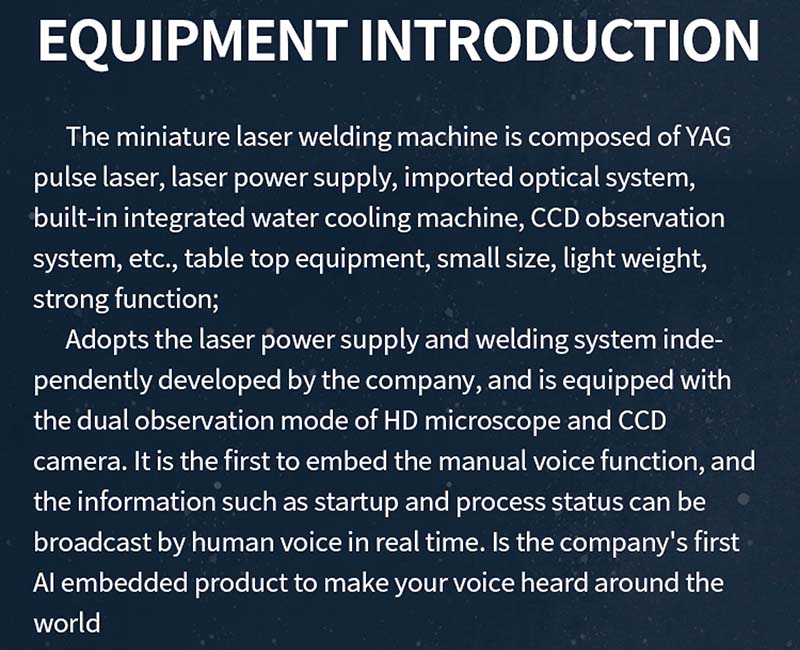

Features:

1. Compact design, saving space in the workshop or studio, and convenient transportation.

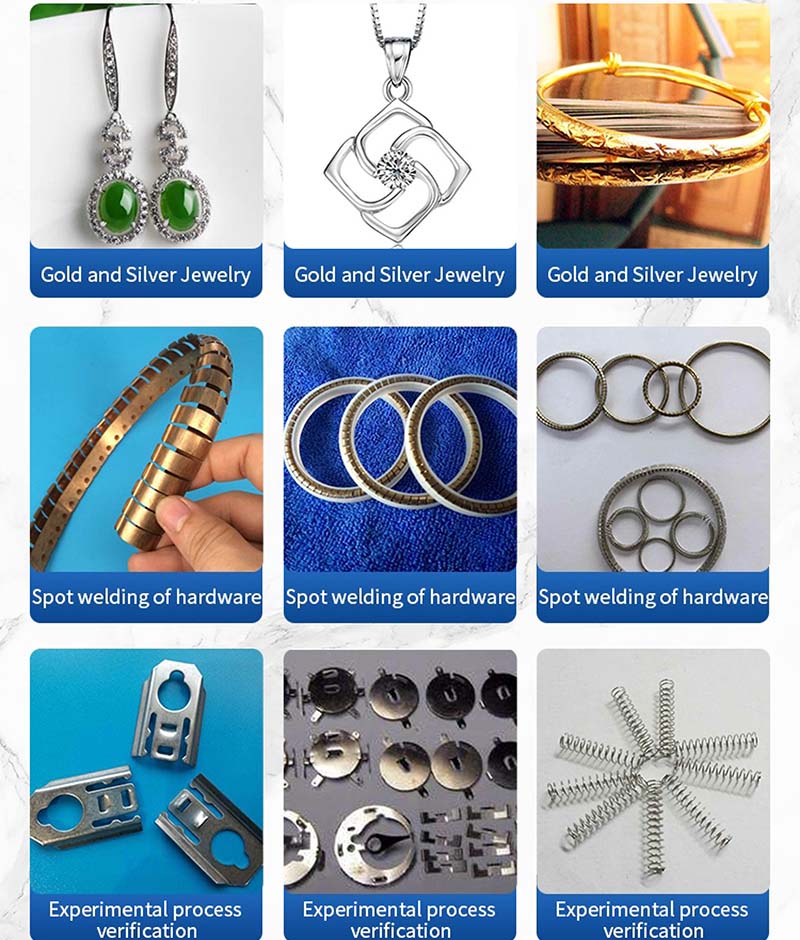

2. The microscope is displayed synchronously with the CCD, which is very convenient for observation.

3. The microscope adopts the best brand in China, which is 1.5 times the cost of other ordinary microscopes.

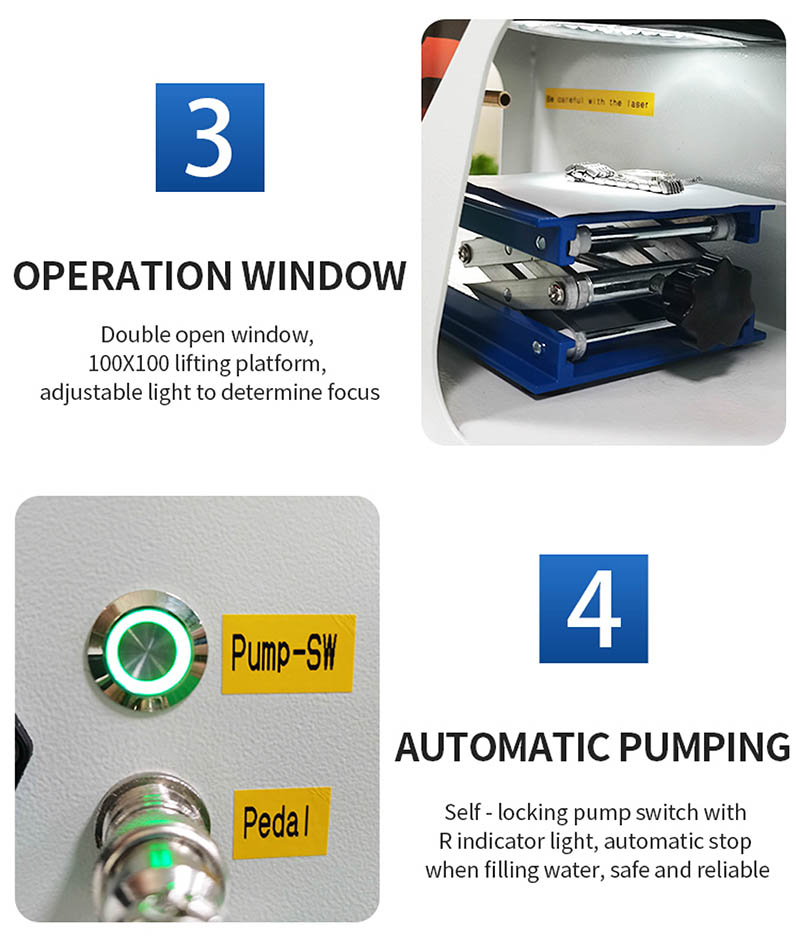

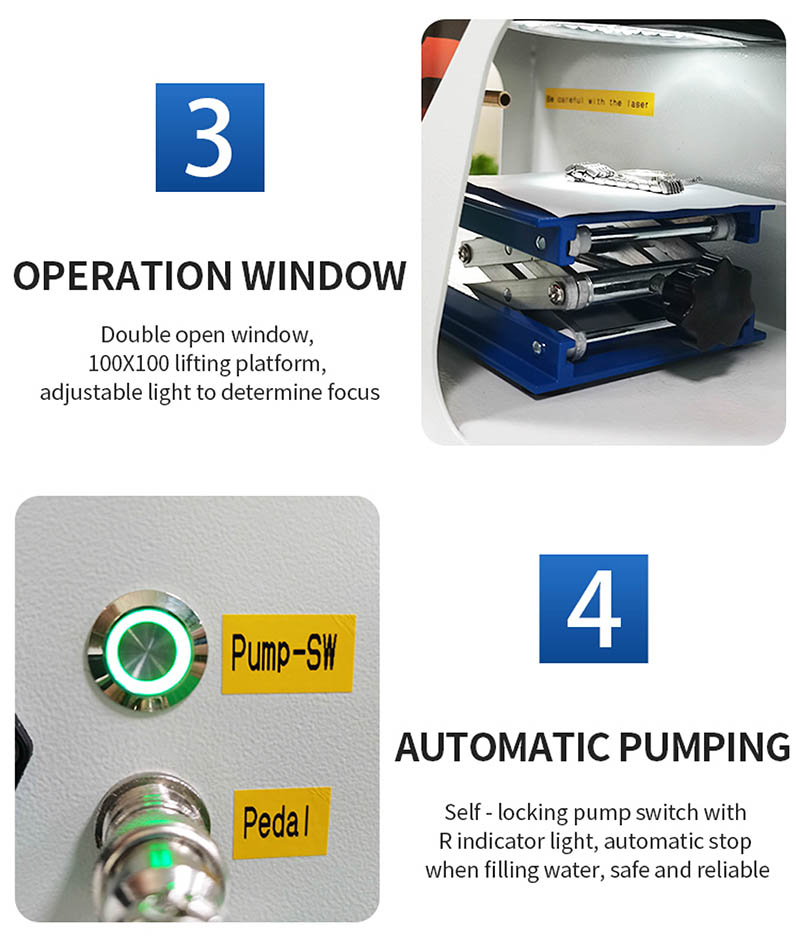

4. Automatic pumping, one-button operation, plug in the tube, enter the password, automatically add water.

5. Air cooling reduces heat and maintenance costs.

6.Color touch screen, friendly human-computer interface.

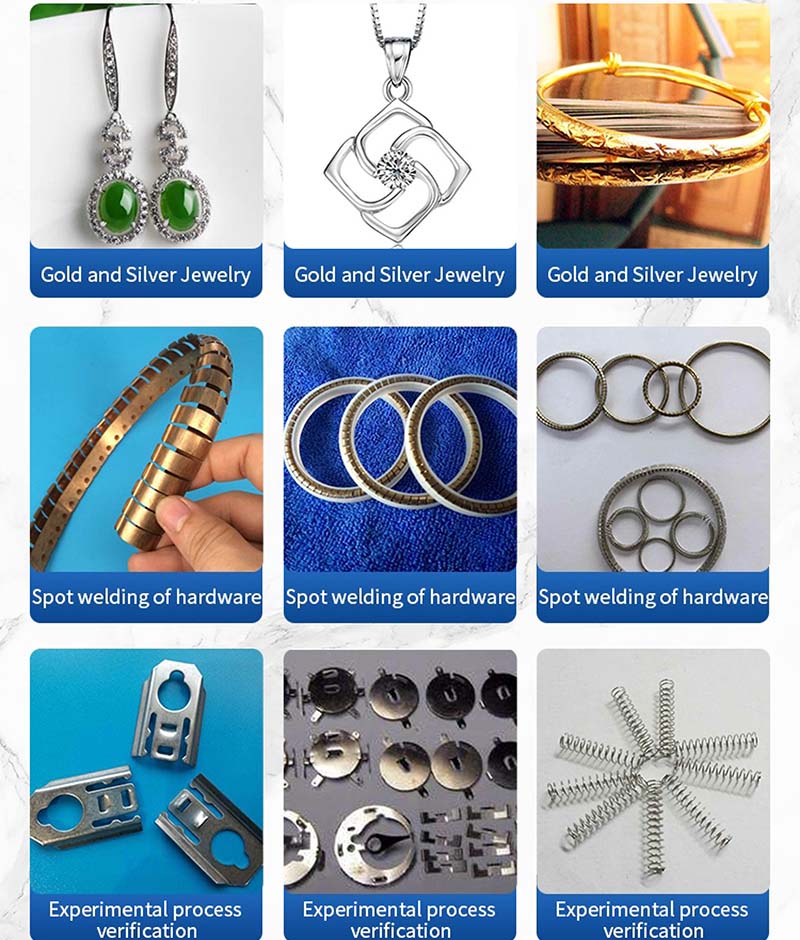

Application:

Suitable for laser welding of gold and silver jewelry, laser welding of stainless steel jewelry, manual laser welding of fine metal parts.

Technology parameter:

|

Input voltage

|

AC220V

|

|

Laser frequency

|

1.0-15Hz

|

|

Pulse Width

|

0.1-10ms

|

|

Spot adjustment range

|

±3.0mm

|

|

Maximum laser power

|

60W/100W/150W/200W

|

|

Machine power consumption

|

3KW

|

|

Aiming and positioning

|

Microscope and CCD

|

|

Ambient temperature

|

≤30℃

|

|

Cooling method

|

Water cooling

|

|

Operation method

|

Touch control

|

|

Laser wavelength

|

1064nm

|

manager@dapeng-laser.com Whatsapp:+8618565695703 Contact KENDY and send you machine teaching videos and manual for free.