It has excellent repair effect on defects such as ductile iron, gray iron and stainless steel, and has fast welding repair speed, no color difference or small color difference after welding, and is suitable for the production of factory scale.

Features:

1. Processing speed is fast;

2. Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials)

3. Local heat treatment of the parts;

4. It can process complex shapes of parts and small parts, and can also process in vacuum;

5. No noise, no pollution to the environment;

6. Combine with computer technology to facilitate automation;

7. Improved existing product structure and materials due to advanced processing methods

8. Can improve the quality of the workpiece.

9. No pre-heat treatment is required, and the workpiece will not anneal after welding;

10. Deformation-free collapse;

11. No pores and trachoma;

12. Can be used for cracks, collapses, corners, sand holes and repairs after use of the mold;

13. Different hardness hardness materials (such as: HRC60) can be obtained by using materials with different hardnesses. The toughness of the cold die and the cutting edge of the cutter can also be repaired, which eliminates the complicated preheating and heat preservation processes of ordinary argon welding.

Application:

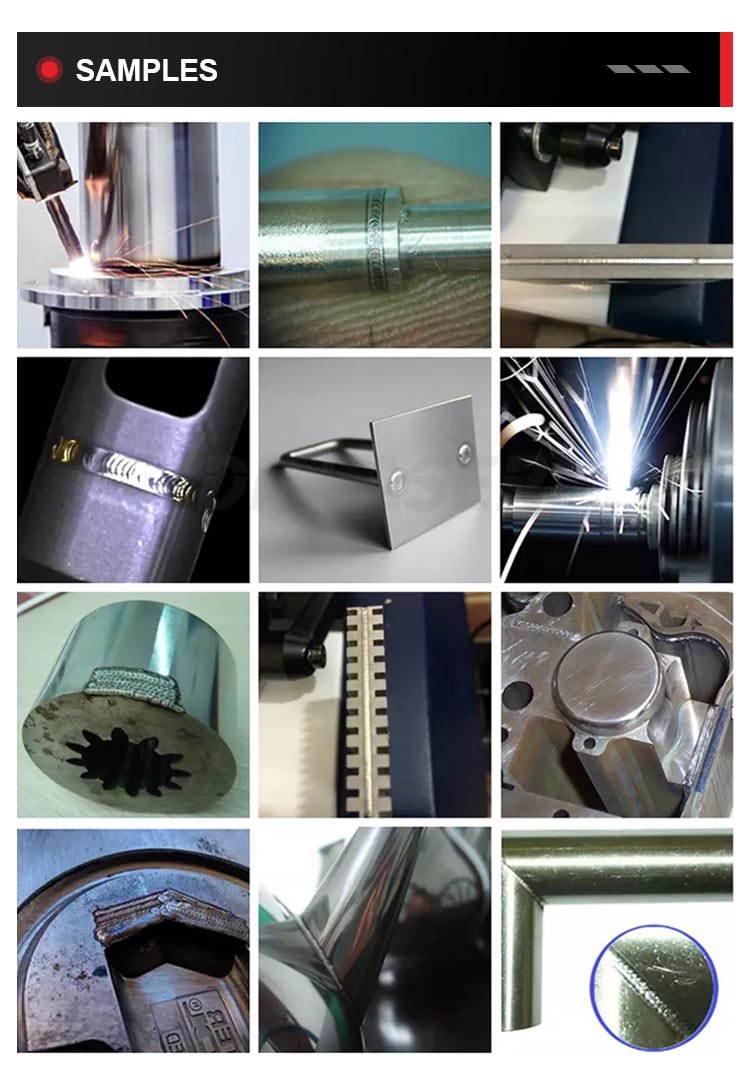

Mold industry

1. Injection mold 2, stamping die 3 die-casting die 4 rubber die 5 copper alloy die

Foundry industry

This welder also has a good performance in casting defects. Quick and precise repair of the pores, slag holes, shrinkage holes, etc. during the casting process.

It has excellent repair effect on defects such as ductile iron, gray iron and stainless steel, and has fast welding repair speed, no color difference or small color difference after welding, and is suitable for the production of factory scale.

Various workpiece parts repair industry

This machine can perfectly repair shafts, teeth and other workpieces.

Technology parameters

| Model | DPH-400 |

| Maximum laser power | 400W |

| Power consumption | 11KW |

| Laser welding frequency | 1-20HZ |

| Laser welding depth | 0.1-3mm |

| Pulse width | 0.5-20ms |

| Spot size | 0.2-2mm |

| Laser wavelength | 1064nm |

| Power required | three phase 380VAC±15% 50HZ 40A above |

| Cooling way | Water cooling |

| Observation system | Microscope |

| Movement workbench |

Welding head XYZ electric control; Welding table Z electric control, XY by manual |

| Worktable | 400*300mm |

| Consumables | Xenon lamp, protective lens (Recommend buy 2 more units) |

This welder also has a good surface in terms of casting defects. Quick and precise repair of the pores, slag holes, shrinkage holes, etc. during the casting process.

Excellent repair effect on defects such as ductile iron, gray iron, stainless steel, etc., fast welding repair speed, no color difference or small color difference after welding, suitable for factory scale production.

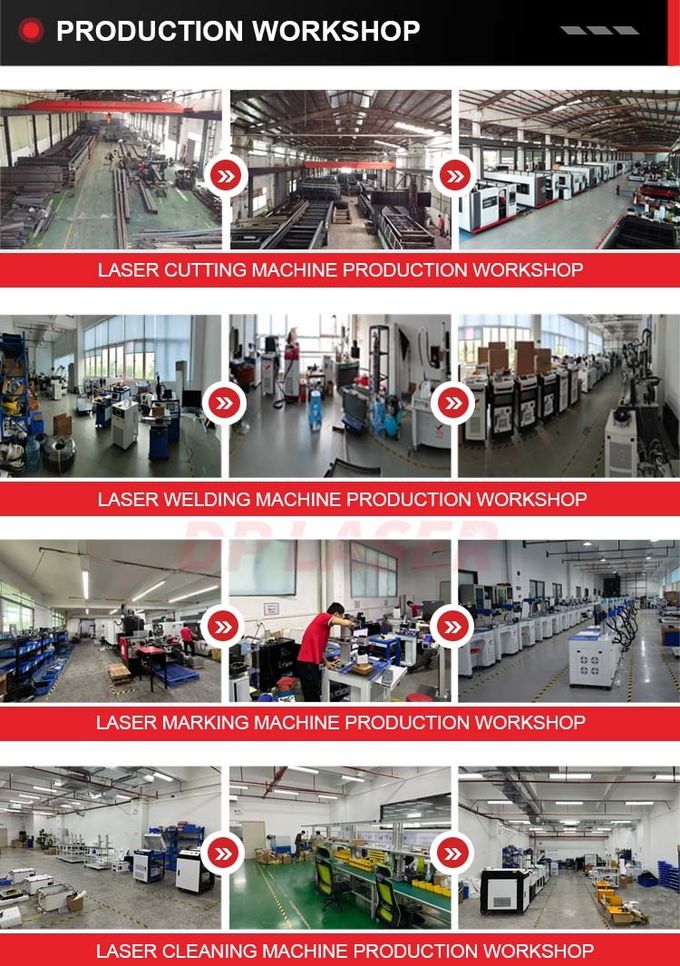

We are manufacturer of fiber laser cutting machine with 12 years of production experience.We offer complete machine solution,also provide laser source,CNC controller ,laserhead, water chiller,servo,custom made machine table,training and service,etc. one-stop solution!

Our core advantages:

1) Top 5 laser company in China. Sold 4500 units of laser machines in China market per year, with best price.

2) Usually have 50 units of laser marking machine(Fiber, CO2, UV, Mopa) in stock, lead time 3-5 days.

3) Fiber Laser cutting machine, (1000W-20,000W laser cutter), usually sell 50 units/month in China.

We are looking for distributor. Price is more competitive.

We have 250MB videos and manual reference, if you want, we can send you for free, please leave message.